Business Unit

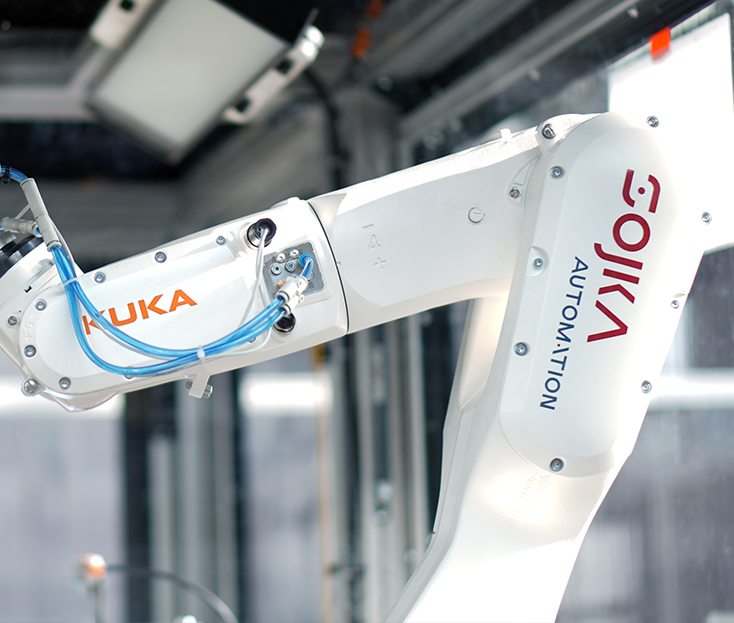

Sojka's Advanced Automation business unit develops future-oriented production systems for industrial customers with corporate structures. Our many years of experience in project planning according to customer standards and firmly defined specifications with regard to programming, construction and documentation conditions make us a strong partner for you. High-quality materials and well thought-out control programmes guarantee a high degree of robustness and durability of the systems and, at the same time, extraordinary process reliability.

Benefit from our clear structures and standardised internal and operational processes - which form the basis for the successful realisation of special machine construction projects.

Your Advantage -

Advanced Automation

A wide range of solutions for the most demanding tasks

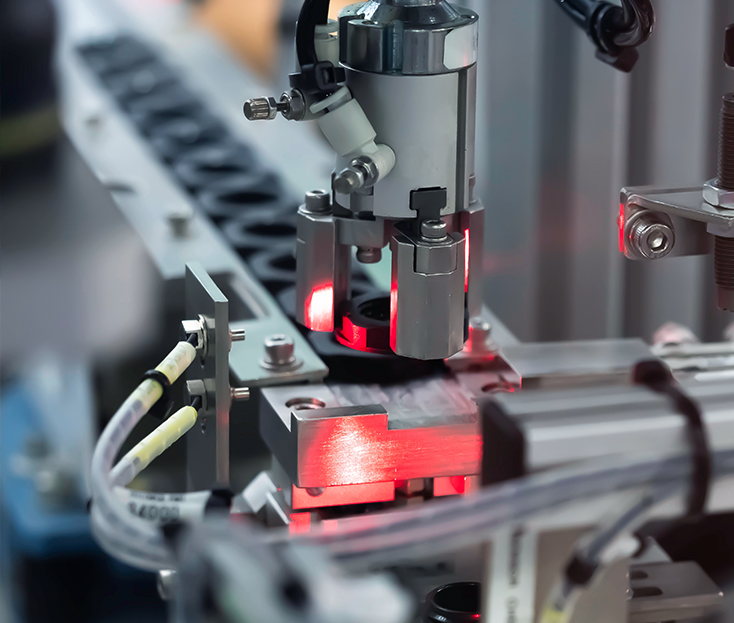

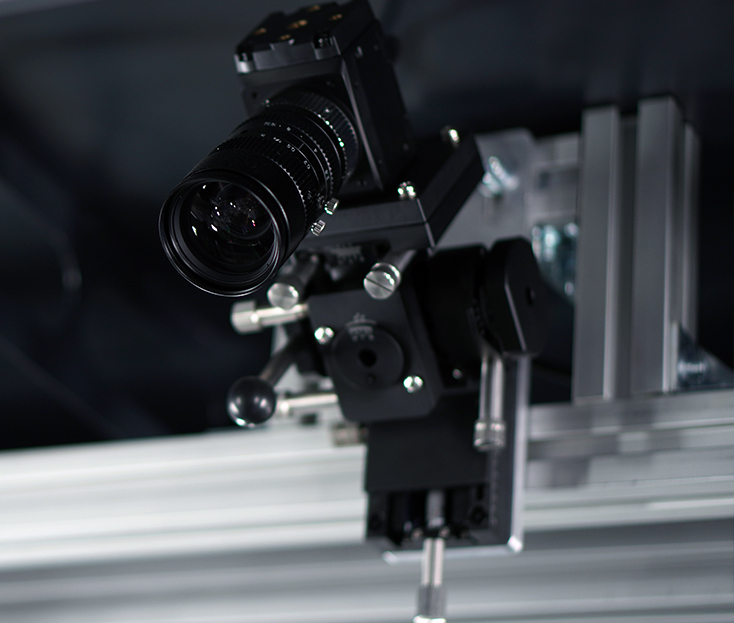

Advanced Automation is characterised by complex tasks and challenging framework conditions. Consequently, the implementations and approaches are also complex in nature and highly individual. With our solutions, you will always find the right answer to your automation questions.