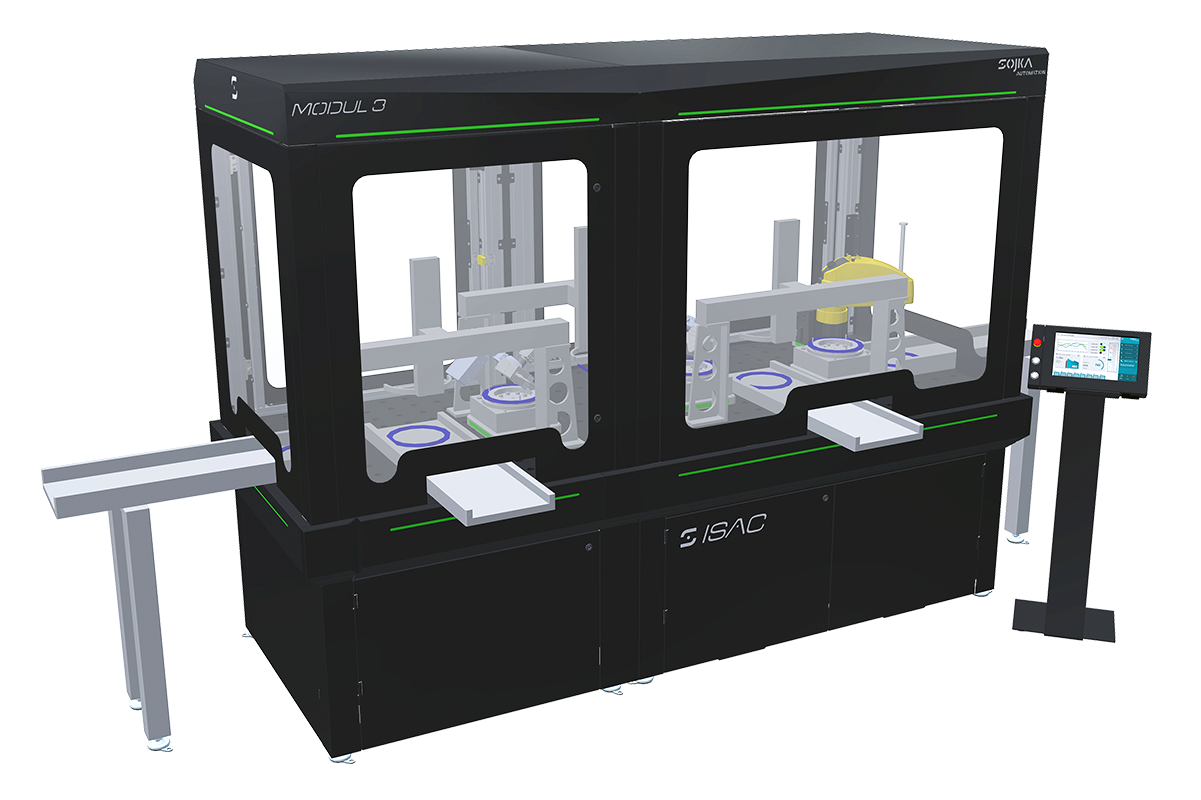

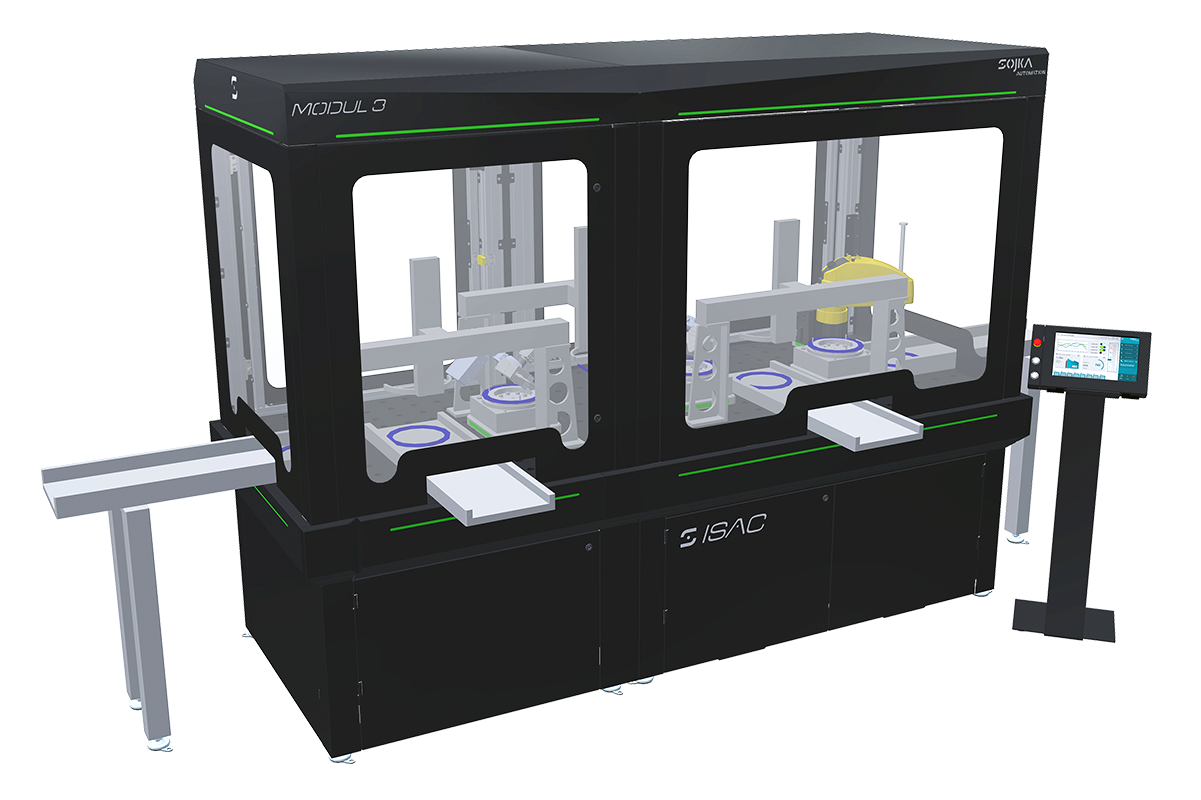

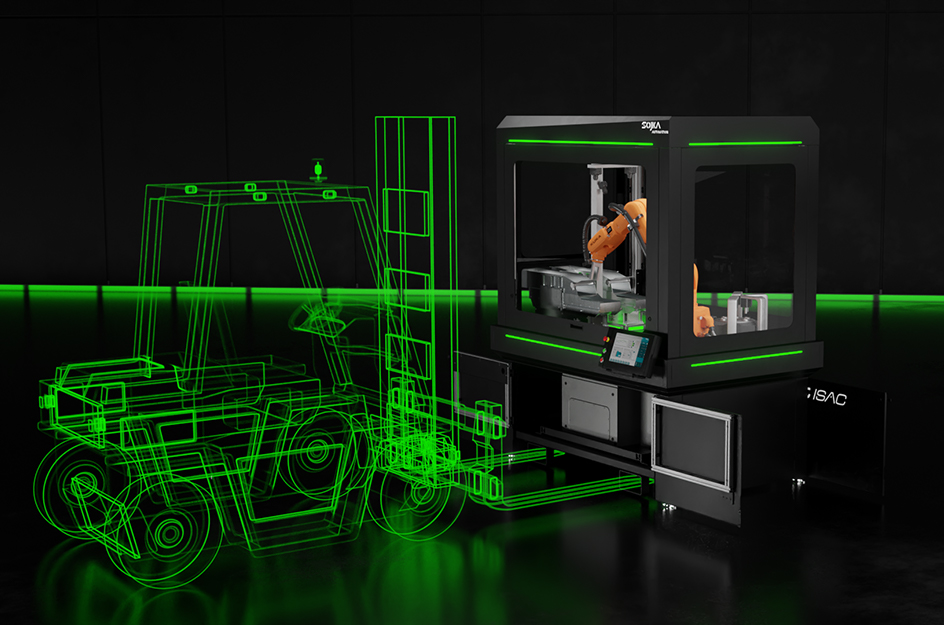

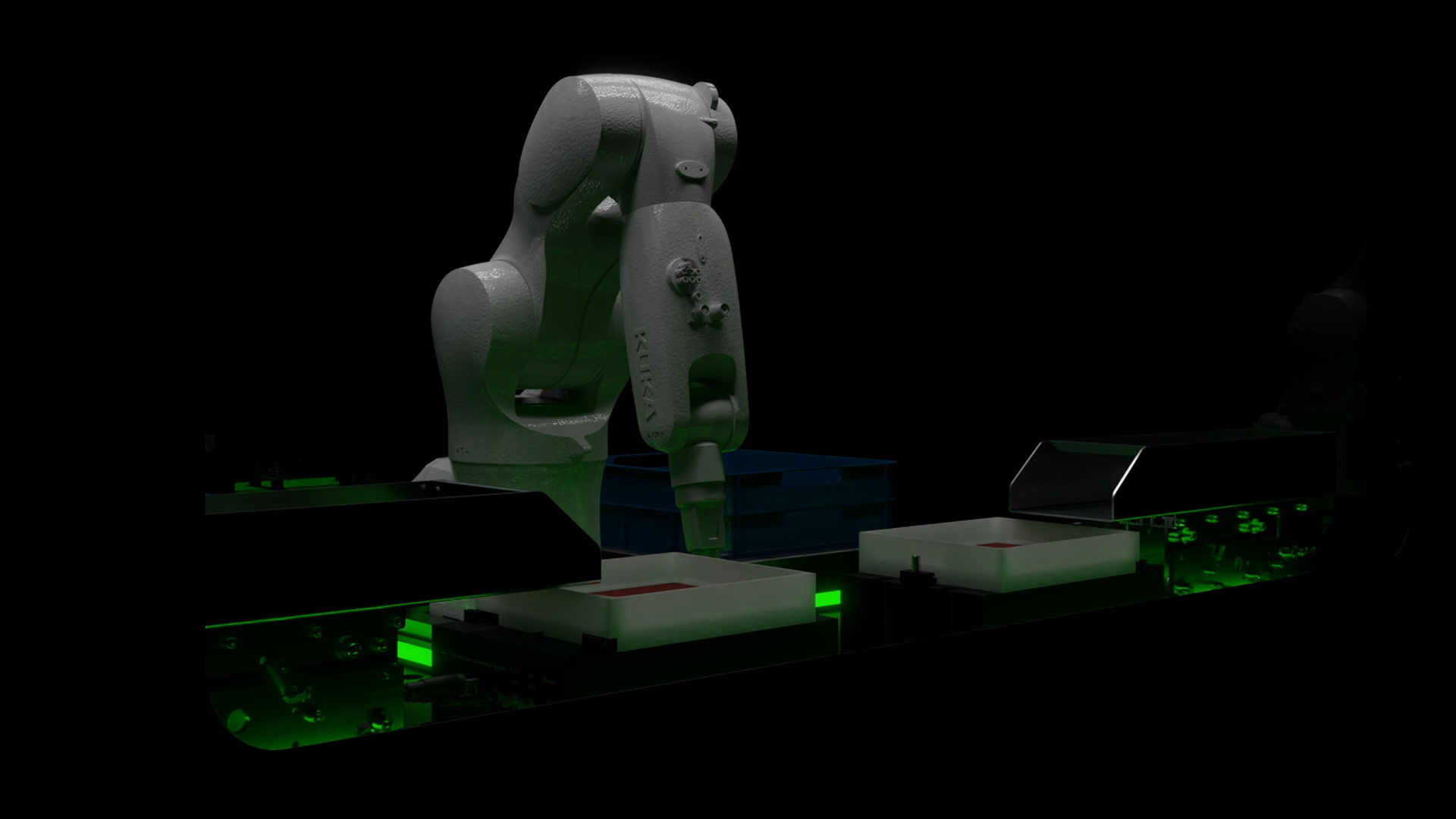

Assembly Automation

ISAC® Assembly enables you to increase production efficiency through semi- and fully automated assembly of a wide range of parts and components.

Industrial Image Processing

ISAC® Check uses state-of-the-art image processing technology to reliably find every defect characteristic while consistently documenting the testing process. Quality assurance 4.0 guaranteed.

Pick & Place

Accelerate your production by harnessing the potential of ISAC® Speed: Maximized productive output facilitated by minimized cycle times. High repeat accuracy and precision continuously ensure high quality.

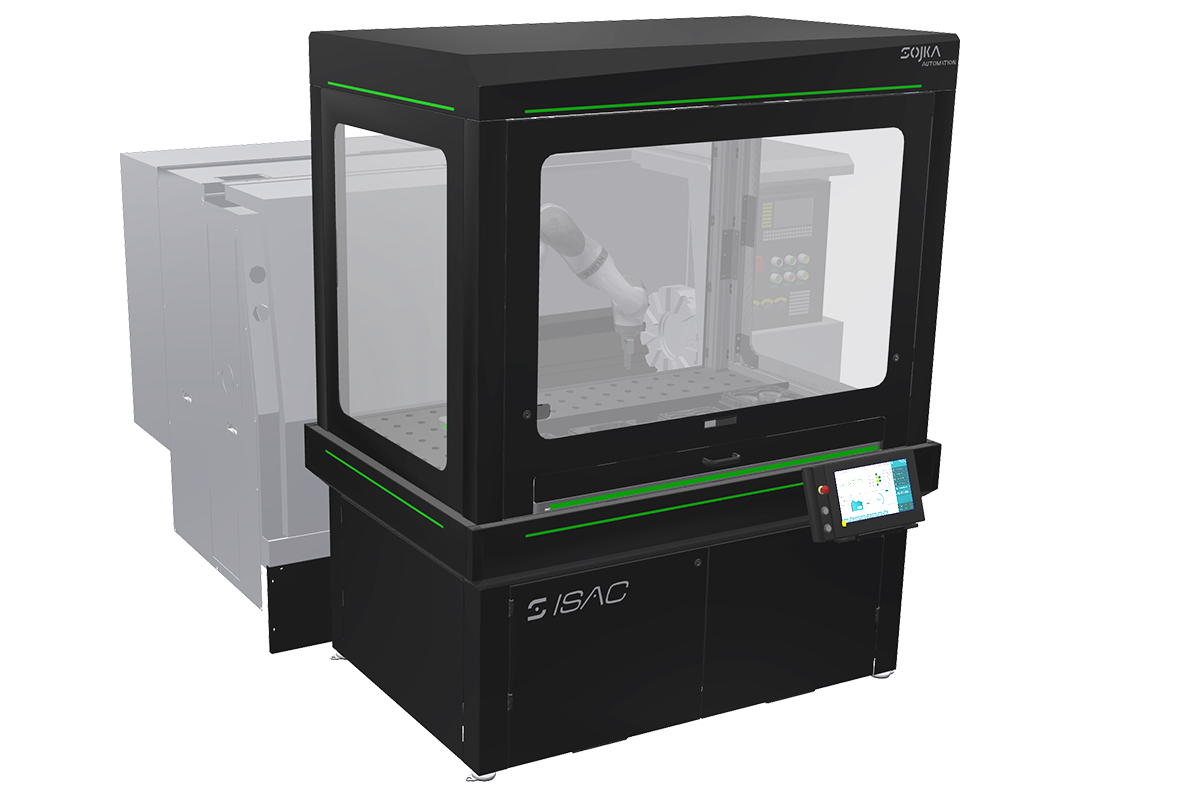

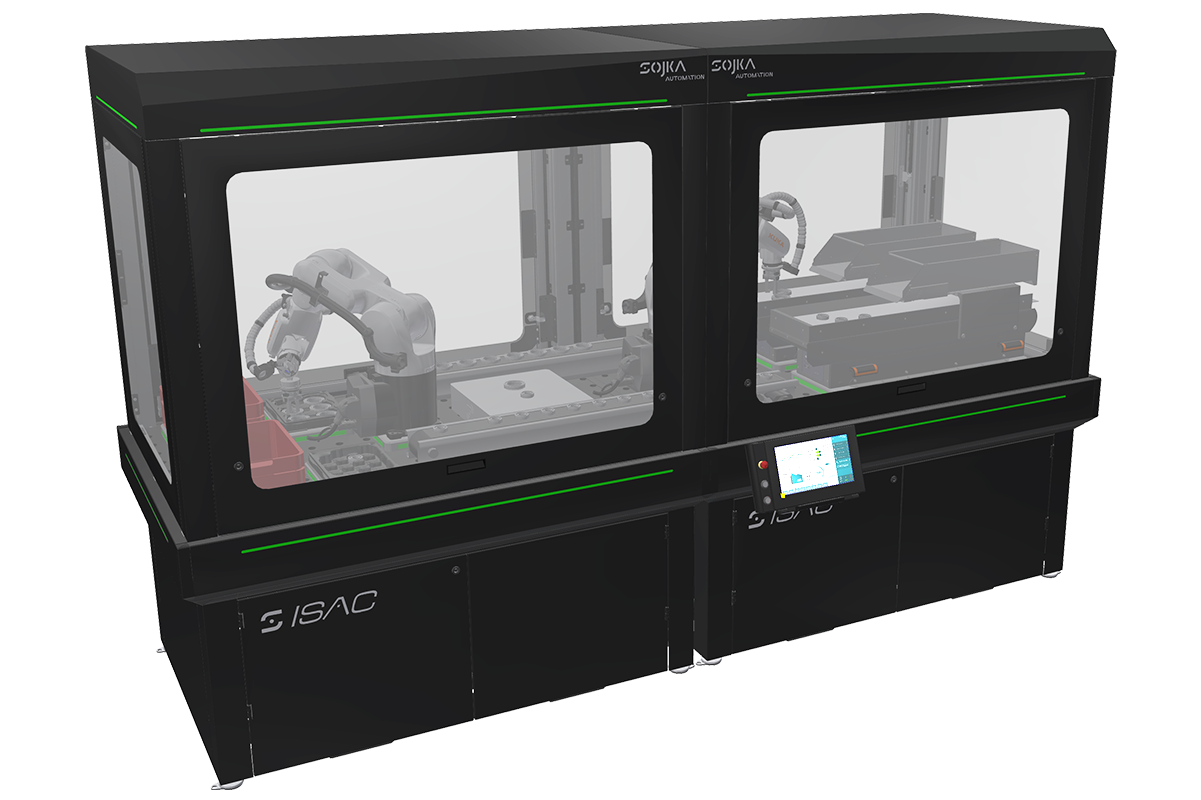

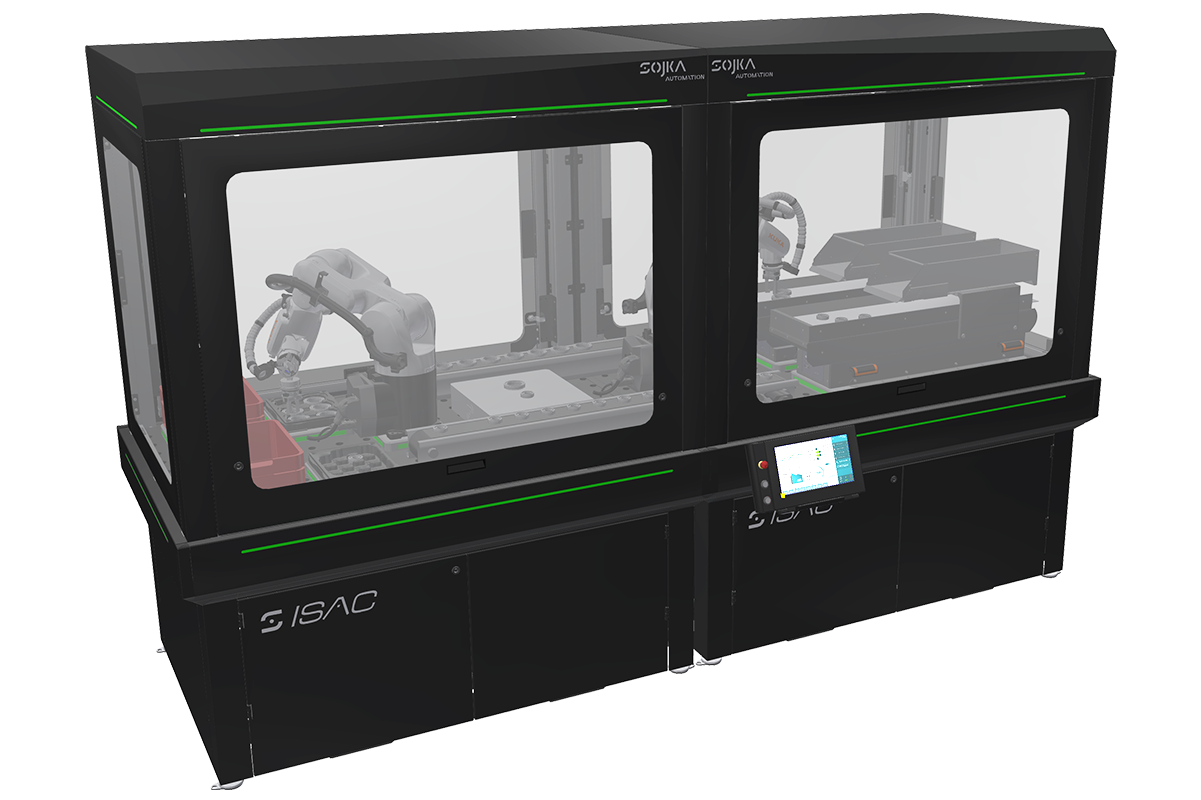

Machine Tending

ISAC® Equip relieves your most precious resource – your employees – from having to carry out monotonous and time-intense routine tasks such as machine tending or unloading components and materials from different machine tools.

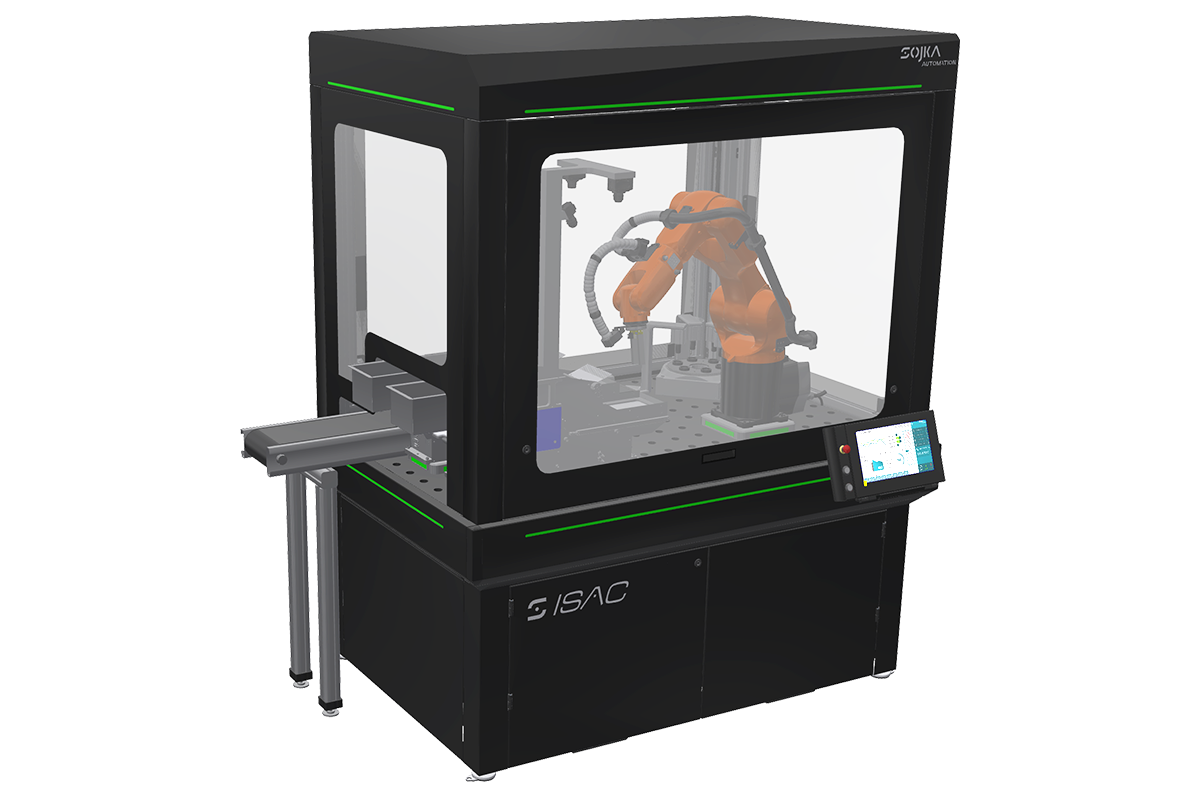

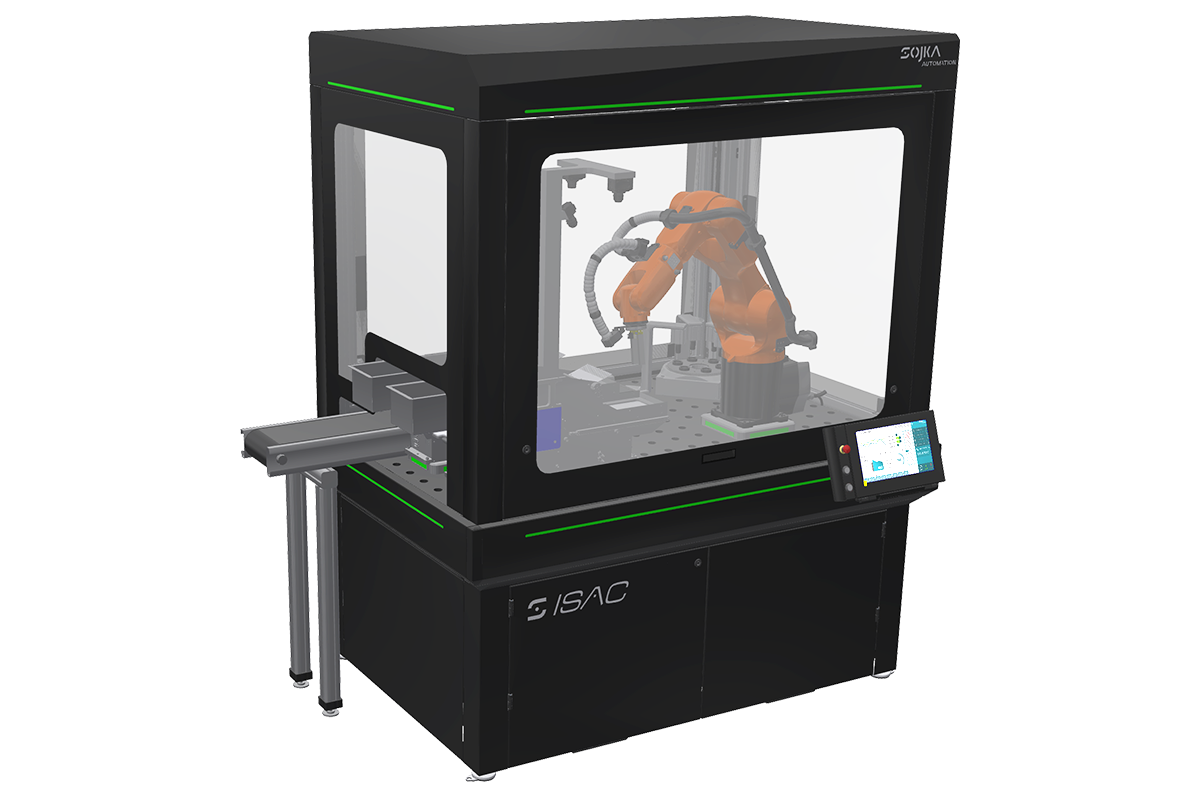

Bin Picking

Use the most efficient module available on the market: ISAC® Bin Picking combines state-of-the-art camera-based feeding technology with compact, steady conveyor technology and supports a wide range of VDA container dimensions.

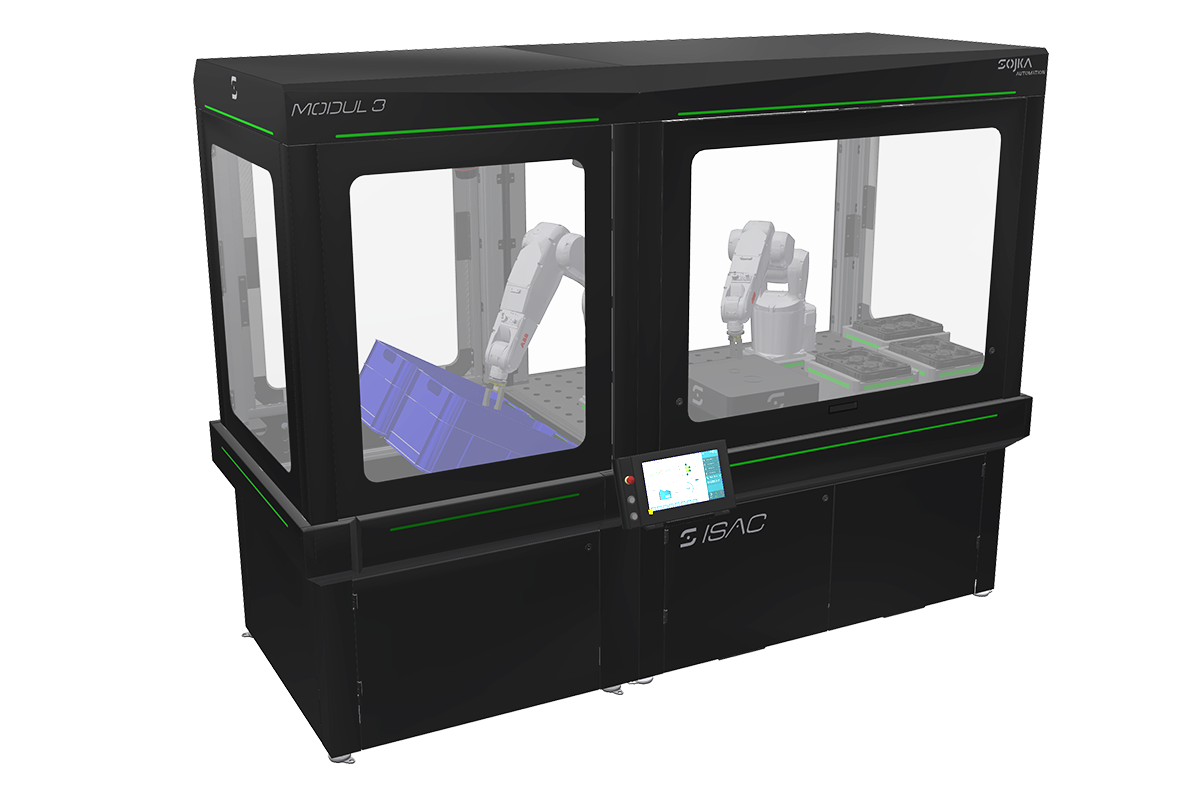

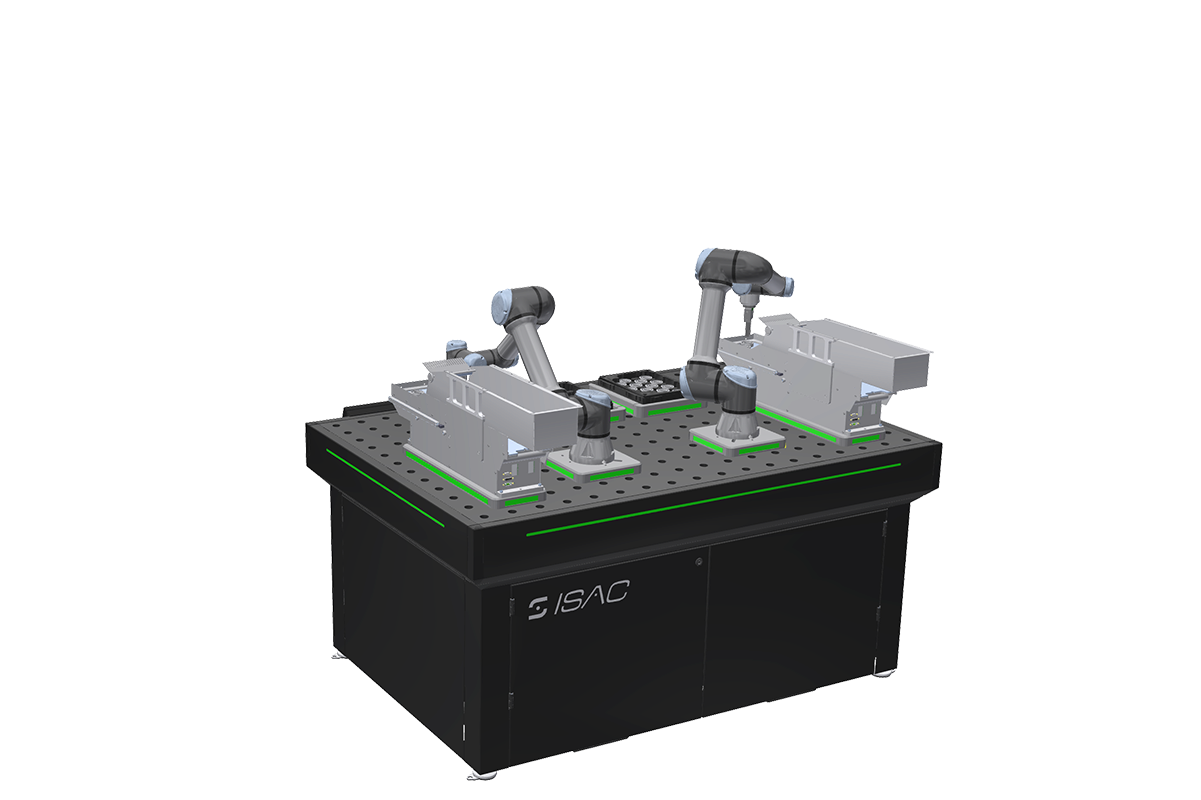

HRC Applications

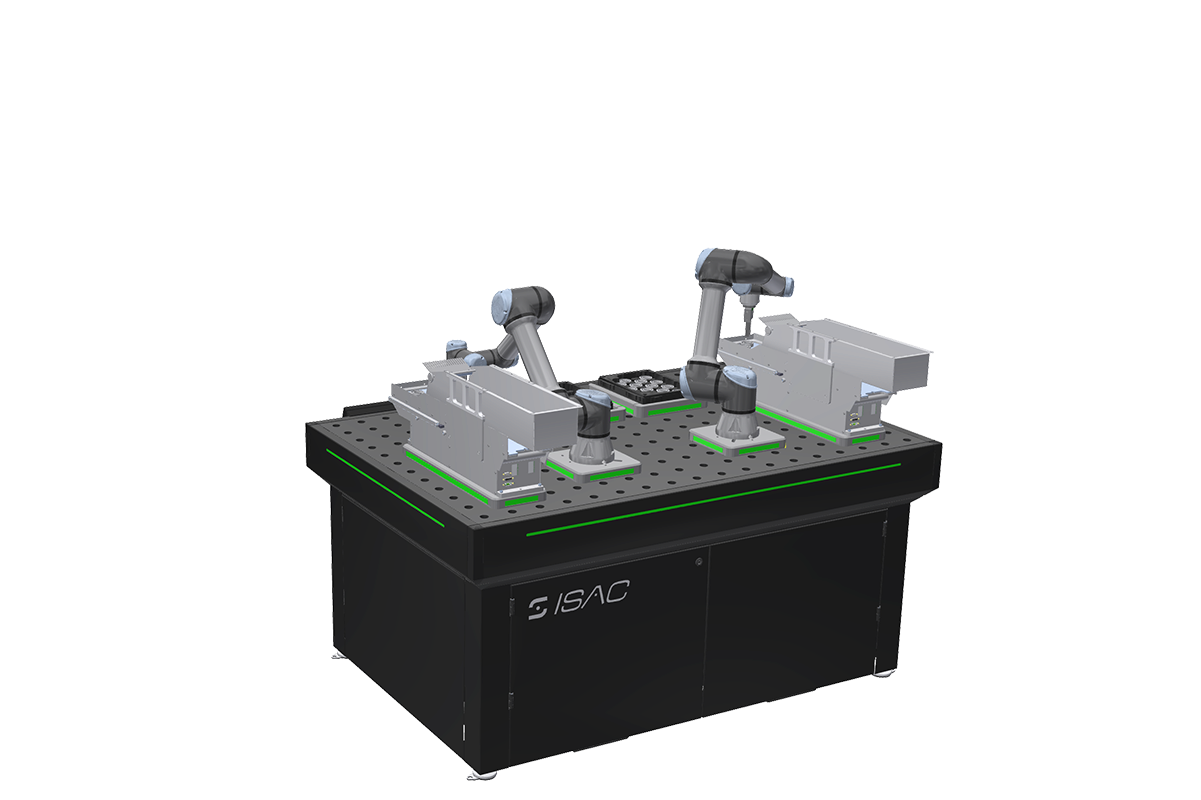

With the ISAC® Collab, we are taking human-robot-collaboration to a new level. In compliance with the highest safety standards, we integrate your machine operator into intricate process steps. Eliminating monotonous tasks creates capacities for the implementation of complex operations.

Special Solutions

If your requirement or process is not covered by our preconfigured ISAC® models, we will use our patented platform to design a custom automation cell tailored to your specifications.

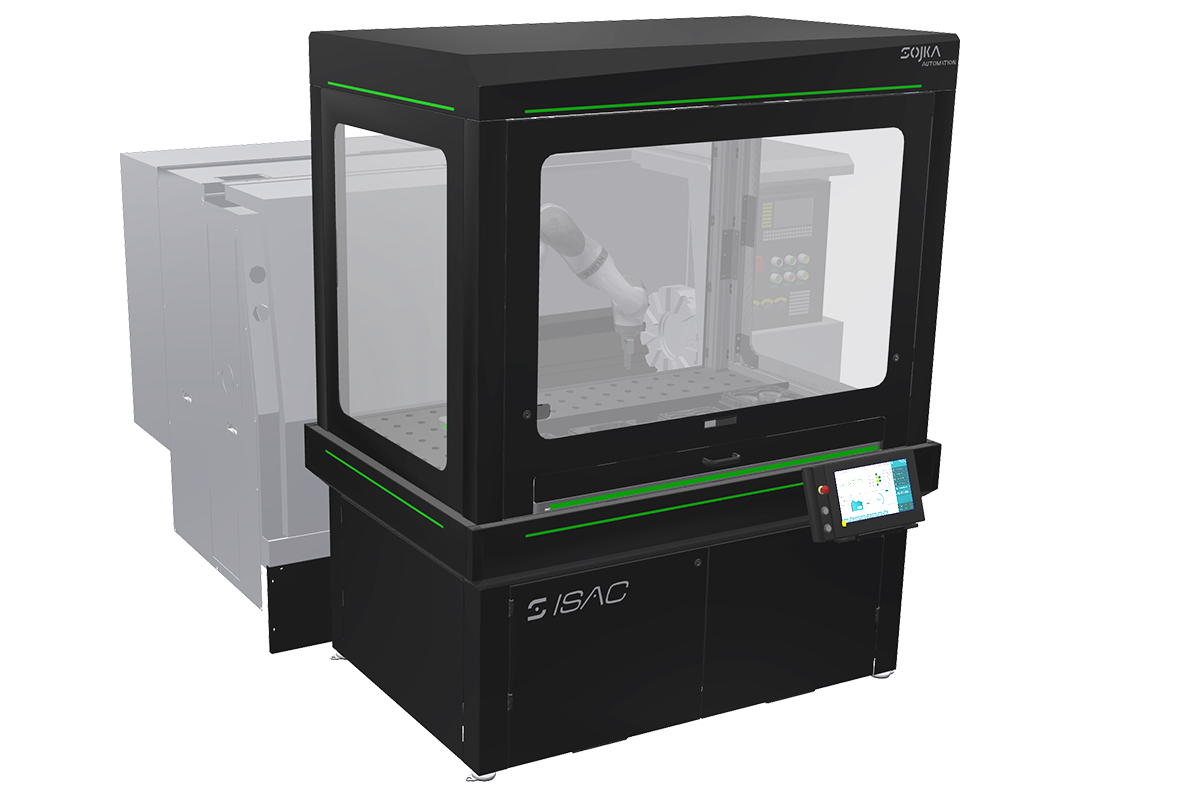

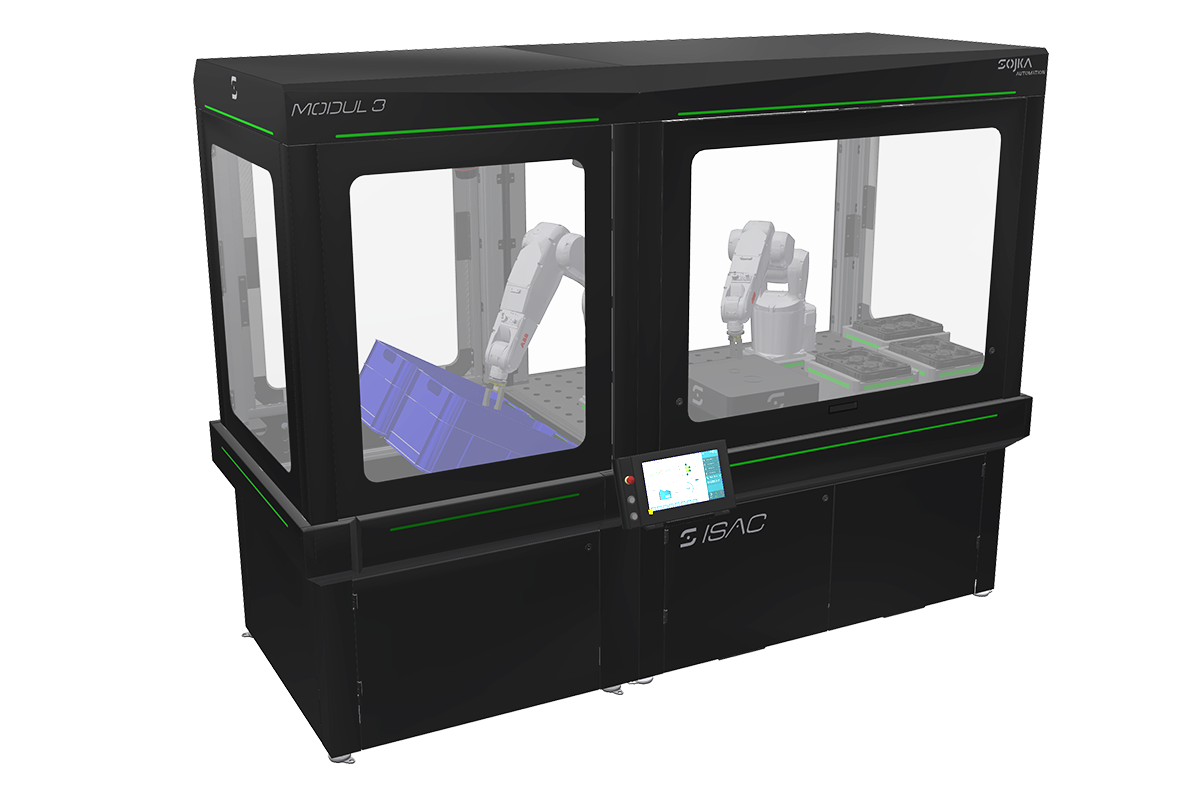

Modular, simple, and scalable

Depending on your requirements, ISAC® can either be set up as a stand-alone module or combined into a complex multi-cell assembly line without any machining. Quick and simple linking of the cells and integration of actuators in the assembly space allow for a low-effort maximum degree of scalability.

As flexible as you have to be

Rapidly changing market demands and customer requirements call for the ability to quickly make adaptions to the production side.ISAC® is here to show that achieving both standardization and flexibility in automation are not contradictory goals. Its compact but rigid design and integrated control cabinet allow for straightforward and quick positioning in the installation space.

The sustainable solution to product variance

Due to its high degree of standardization and component compatibility, ISAC® is capable of being equipped with a wide range of componentswhile still allowing for full flexibility for a conversion, should your requirements change in the future. This saves you money and resources.

Intuitive operating concept – Smart handling

ISAC® ET (easy touch) enables the operator to control sophisticated processes in an intuitive and user-friendly manner.Simplifying the machine operation permits the worker to concentrate on the truly challenging tasks.Furthermore, ISAC® ET grants you access to the extensive support functions of our WE CARE servicing and maintenance program.

IOG® – casting light into the darkness

Visionary and intuitive operator guidance facilitated by visual signals optimizes plant operation as well as system restarts after downtimes.

Captivating Design

“Form follows function” certainly applies to ISAC®. However, our aspirations for this system go beyond that. ISAC® sets new standards for design aesthetics and ergonomic handling. Want an example? All surfaces are fully covered and show no visible bolted connections.

- Blister & Tray Placement

- Bulk Material Separation through Vibration

- Position-oriented Detection through Image Recognition

- 3D Bin Picking

- Spiral Conveyors

- Manual Feeding

- Trays

- Carrier

- KLT Container Modules

- Bulk Material

- Blister

- Deep Learning – AI-powered Image Processing

- Automated Measurement with 3D Image Processing

- 2D & 3D Surface Testing & Inspection

- Presence & Completeness Checks

- Geometrical Testing

- Checking of DataMatrix Codes, QR Codes, etc.

- Portal Systems

- Rotary Tables

- Linear Transport Systems

- Belt, Rope Belt, and Chain Conveyors

- Robot Systems

- Kuka, Fanuc, ABB, Epson, Universal Robots

- Scara Robots

- 5/6 Axis Robots

- Delta Robots

- Feed Systems

- Roll to Roll Foil Application Technology

- Assembly Systems

- Handling Systems

- Testing Modules (camera-based, mechanical, electrical, and thermal testing modules)

- Bonding & Dosing Systems

- Barcode Reader

- Marking Systems (Laser, Offset, Needle Embossing)

The systems that are used for this purpose act autonomously in a targeted manner.

Robotics and robot technology play a key role in facilitating this process.

Human operators are solely needed to control and monitor the automated systems, which frees up time in their work schedule and enables you to assign them to other departments.

An automation cell is an artificial system designed to carry out functions during the production process. Cells combine the highest possible standardization on the lowest possible physical space with a multitude of options for customization. This makes them viable for multifunctional applications.

Their value lies in increased productivity and flexibility that leads to increased economic efficiency for the businesses that deploy them.

With ISAC®, we offer you flexible, modular, and future-oriented automation. Due to a high degree of standardization and efficient resource management, the investment needed for a complete ISAC® ranges from € 40,000 to € 250,000, depending on the model and required process technology. At this price, we offer an economic and efficient access to the field of automation, particularly for small and medium sized businesses.

Sounds convincing?

ISAC® is only one of many products by Sojka Automation. Discover more cutting-edge products and solutions for your business.