Frequently Asked Questions

Generally speaking, every industrial robot available on the market exists for a reason. The main differences between models are:

- Cycle time

- Repeatable accuracy

- Range of motion

- Cleanroom classification

- Price

- Optimized connectivity to other system components (cameras, sensors, control systems)

- User-friendliness

Get in touch with us, we will gladly advise you!

We offer proven knowhow in the fields of:

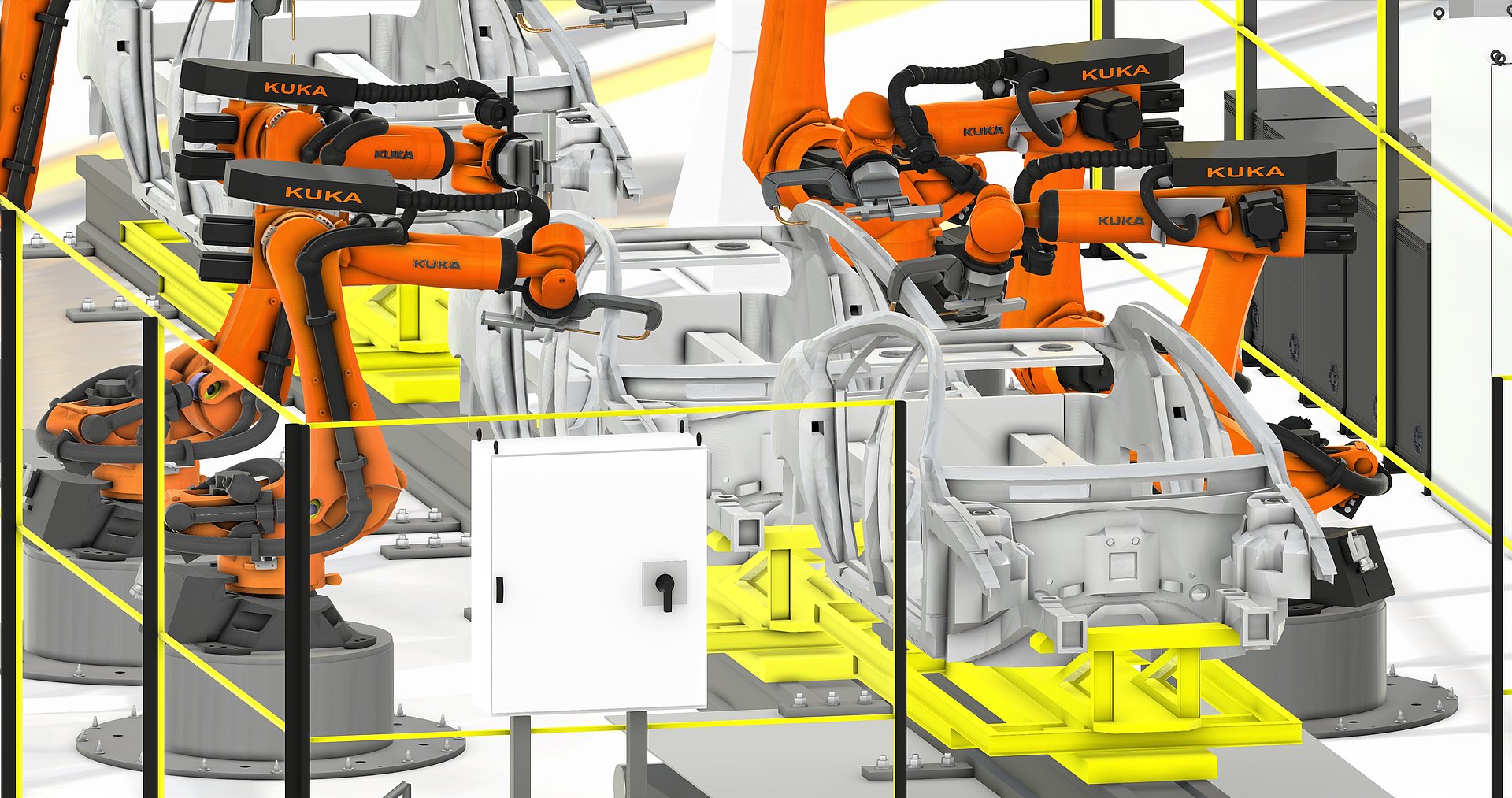

- Path application processes such as welding, bonding, or weld seam testing

- Processing procedures such as cleaning, resistance spot welding, flow drill fastenings, blind riveting, clinches, stud welding, grinding, or drilling

- Fusion processes

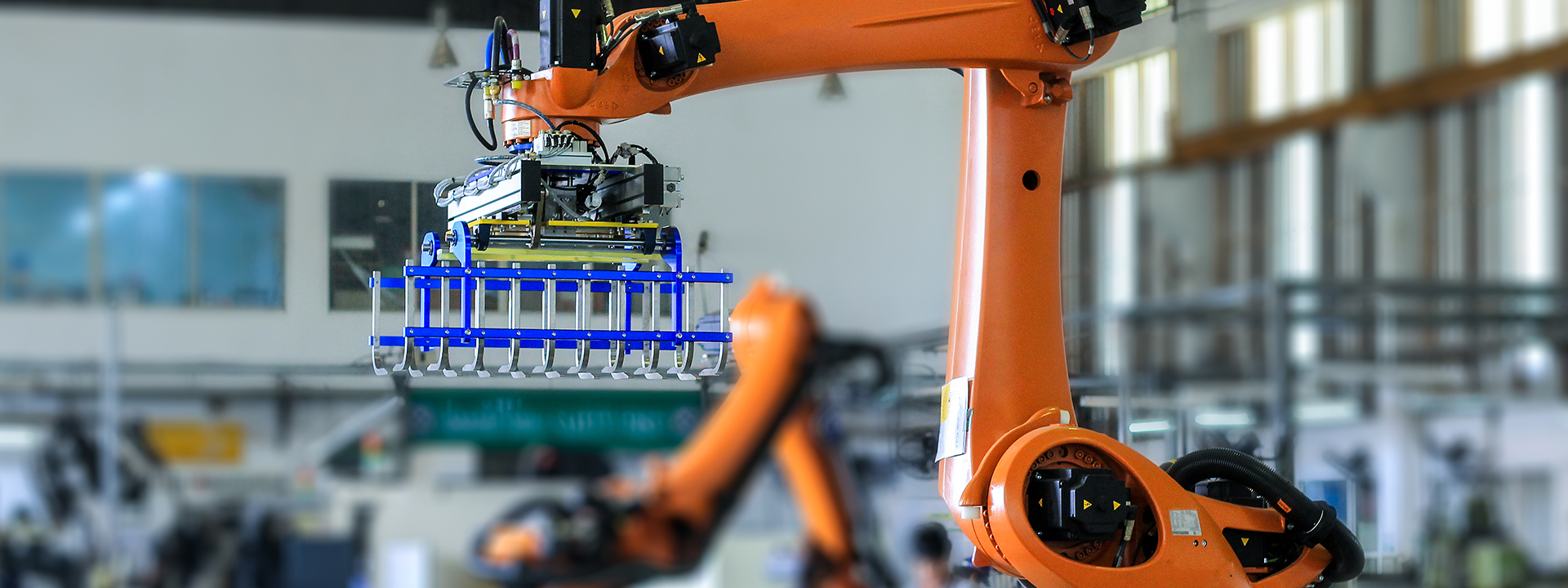

- Pick & place applications such as gripping, sorting, or palletizing

The price range for a complete system solution varies with the complexity of your requirements. Industrial robots, such as 6 or 5 axis robots, or Scara, as a single system component, range between 20,000 and 80,000 euros depending on payload, range of motion, cycle time, and cleanroom classification.